Stop file UTW-4.0-U

The holes are used to stop the wheel buckle ring, also known as the pores with a gear and the card springs. It is a fastener used in the hole. move.

Model :

UTW-4.0-U型

The holes are used to stop the wheel buckle ring, also known as the pores with a gear and the card springs. It is a fastener used in the hole. move. The hole buckle ring with holes has the following characteristics:

Easy to install: The hole buckle is used to process the appropriate groove in the hole to install and use it.

Easy to disassemble: The holes can be disassembled through caliper clamps or other tools.

Strong bearing capacity: The hole with a stoppage ring has good elasticity and can withstand a large axial load.

Good corrosion resistance: The holes are made of stainless steel or other corrosive materials, which are usually made of stainless steel or other corrosive materials, which have good corrosion resistance.

The holes are widely used in the fields of machinery, vehicles, aerospace and other fields.

The following is the specific application of the hole buckle of the holes:

Fixed gear: The holes can be used to fix the gear to prevent the gear axial movement.

Fixed bearing: The holes can be used for fixed bearing to prevent bearing bearing from moving.

Fixed other parts: The hole buckle ring can be used to fix other parts to prevent parts axial movement.

The selection of holes with a barrier buckle needs to be carried out according to different application needs, and it is necessary to consider factors such as the size, material, and bearing capacity of the buckle ring.

Common categories of holes with a stoppot buckle ring:

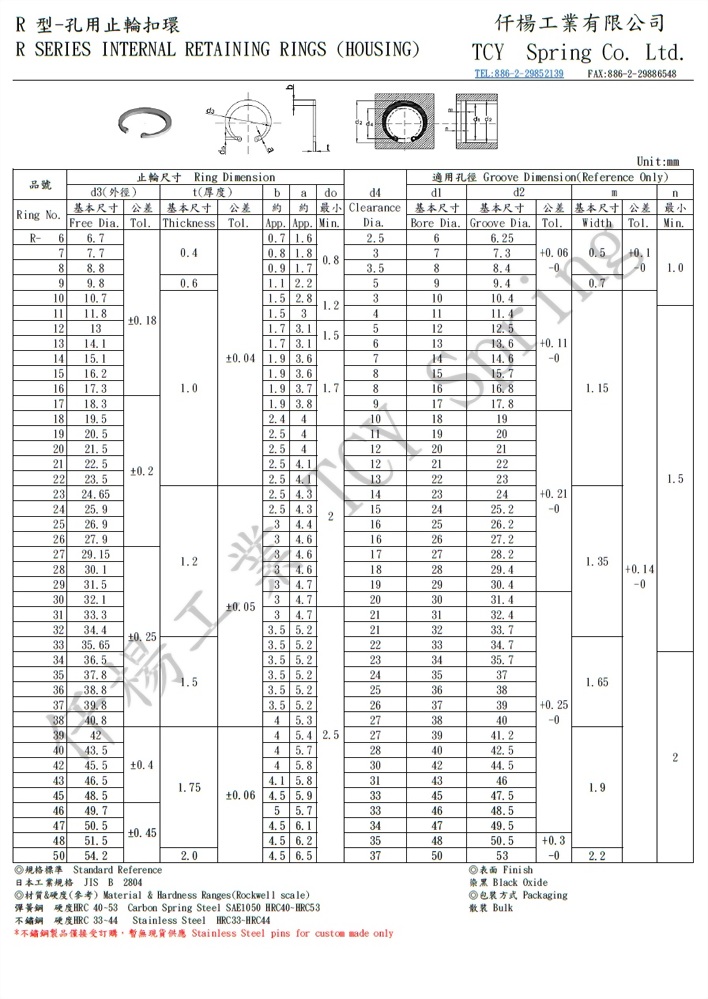

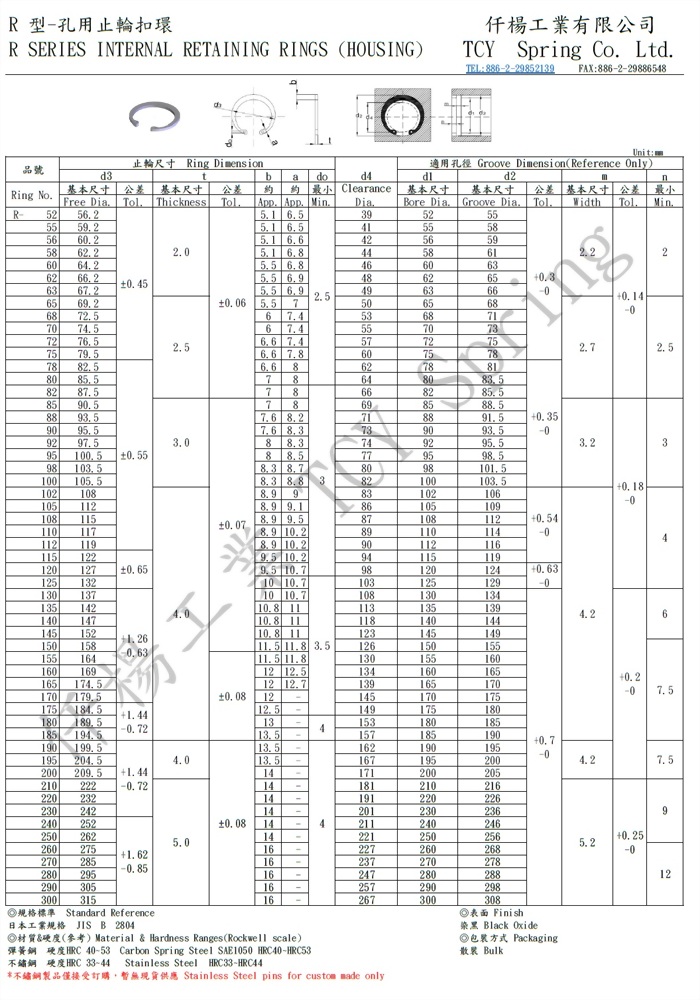

Classified by shape: C -type buckle, E -type buckle, K type buckle, R -type buckle ring, etc.

Classified by material: stainless steel, carbon steel, copper, aluminum, etc.

Classified by the bearing capacity: light load, mid -load, heavy load, etc.

Easy to install: The hole buckle is used to process the appropriate groove in the hole to install and use it.

Easy to disassemble: The holes can be disassembled through caliper clamps or other tools.

Strong bearing capacity: The hole with a stoppage ring has good elasticity and can withstand a large axial load.

Good corrosion resistance: The holes are made of stainless steel or other corrosive materials, which are usually made of stainless steel or other corrosive materials, which have good corrosion resistance.

The holes are widely used in the fields of machinery, vehicles, aerospace and other fields.

The following is the specific application of the hole buckle of the holes:

Fixed gear: The holes can be used to fix the gear to prevent the gear axial movement.

Fixed bearing: The holes can be used for fixed bearing to prevent bearing bearing from moving.

Fixed other parts: The hole buckle ring can be used to fix other parts to prevent parts axial movement.

The selection of holes with a barrier buckle needs to be carried out according to different application needs, and it is necessary to consider factors such as the size, material, and bearing capacity of the buckle ring.

Common categories of holes with a stoppot buckle ring:

Classified by shape: C -type buckle, E -type buckle, K type buckle, R -type buckle ring, etc.

Classified by material: stainless steel, carbon steel, copper, aluminum, etc.

Classified by the bearing capacity: light load, mid -load, heavy load, etc.