Chain Young Industrial Increases Production Capacity of 0.1-0.8 mm Universal Spring Machine

Chain Young Industrial Increases Production Capacity of 0.1-0.8 mm Universal Spring Machine

January 13, 2026, a sunny and breezy day

Increasing Precision Spring Production Capacity, Fully Deploying AI-Style Folded Spring Manufacturing

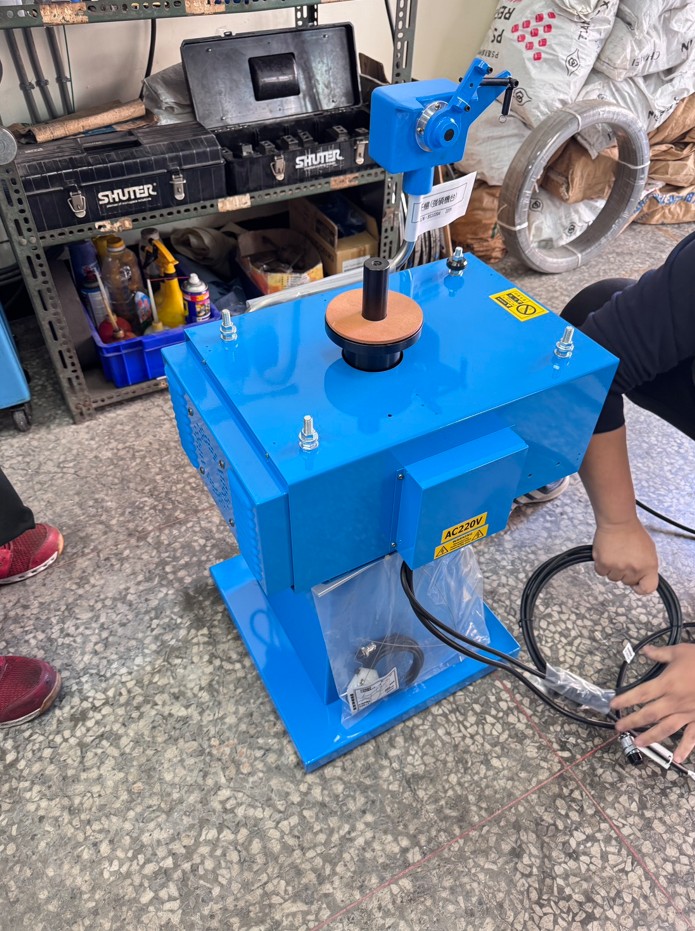

To meet the growing demand for high-precision springs and AI-related applications, Chain Young Industrial has officially introduced a 0.1-0.8 mm universal spring machine. The company plans to complete machine installation and mass production calibration before the Lunar New Year, using this substantial equipment investment to improve overall production capacity and process stability.

This equipment upgrade focuses on AI-formed bending springs, miniature springs, complex geometry springs, and high-consistency mass production, further strengthening Qianyang Industrial's competitive advantage in the precision spring manufacturing field.

Core Value of the 0.1-0.8 mm Universal Spring Machine

- AI device springs, precision electronic component springs, miniature compression springs, tension springs, torsion springs, asymmetrical, irregular, and complex springs, and customized springs with high tolerance requirements.

- Through fully computerized control and a high-resolution servo system, the machine can stably control the angle, zigzag point position, and elasticity consistency, significantly reducing manual adjustment errors.

Why Does AI Zigzag Spring Require a High-End Universal Spring Machine?

- Dimensional consistency

- Angle accuracy

- Stable fatigue life

- High batch repeatability

AI-related springs typically have multiple bends, different force directions, and limited installation space. Only high-precision universal spring machines can stably mass-produce them under small wire diameter conditions.

Chain Young Industrial's equipment investment is a proactive move in anticipation of this industry trend.

Preparing for the Lunar New Year directly impacts delivery time and production capacity. Choosing to complete machine installation and trial production before the Lunar New Year ensures full production capacity in the first quarter of next year. The actual benefits include:

- Shortening the timeline for new AI and electronics customer projects

- Increasing monthly production capacity for small and medium wire diameter springs

- Reducing the unit cost of complex folded springs

- Increasing the ability to simultaneously produce diverse springs

This is not simply an equipment upgrade, but a complete upgrade of production capacity and processes. Chain Young Industrial Increases

Chain Young Industrial's Long-Term Position in Precision Spring Manufacturing

Chain Young Industrial has long focused on the manufacturing of industrial-grade and precision springs, covering:

- AI-engineered linear springs, precision springs for electronics, automotive springs, industrial equipment springs, and customized high-difficulty spring components.

- The introduction of the small wire diameter universal spring machine signifies that Chain Young Industrial has officially included 0.1-0.8 mm precision springs as one of its core processes, using equipment capabilities to support long-term mass production and stable quality.

In the era of AI and high-precision manufacturing, the gap in capacity and quality stems from the gap in equipment level.

Chain Young Industrial chooses to respond to the market's real demand for AI-engineered linear springs, small wire diameter high-precision springs, and stable mass production capabilities through actual machine installation and investment.